Make to Order

Streamline order-to-invoice processes, manage production capacity and eliminate bottlenecks with SYSPRO ERP

Improving profitability in make-to-order manufacturing

If you operate in a make-to-order (MTO) manufacturing environment, being “demand driven” is part of your DNA. Unlike manufacturers that rely only on forecasts, inbound orders drive your production, so you need to manage fluctuations in demand as they happen. How can you link information from sales through delivery and manage the costs of each project, while improving company profitability?

- Streamline order-to-invoice processes

- Reduce inventory costs

- Speed up delivery times

- Manage production capacity and eliminate bottlenecks

- Improve sales and operational planning (S&OP)

- Cut the complexity of financial management

MTO Software - Simplify Your manufacturing operations

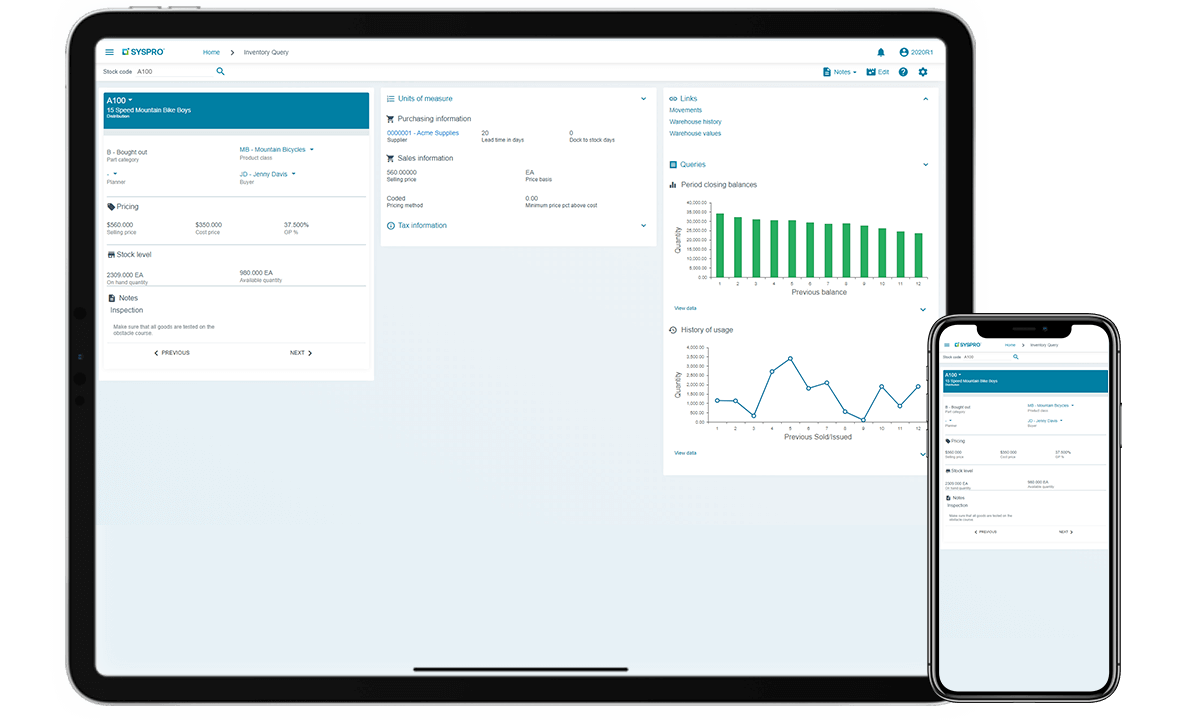

SYSPRO’s flexible, unified platform provides real-time and complete visibility across your operations. Its easy-to-use, powerful functionality is built to help you improve manufacturing and operational efficiency, as well as customer service, throughout the entire enterprise. Here are just a few of the features valuable in an MTO manufacturing environment.

Streamline Quoting and Product Configuration

- SYSPRO’s estimating and quotations features enable you to deliver accurate quotes, quickly. These quotes incorporate a comprehensive evaluation of material and operational costs for single or multiple routings.

- The SYSPRO Product Configurator facilitates seamless rules-based order processing for configurable products.

- Through SYSPRO’s sales order, purchase order and job linking features, you can automatically initiate all actions related to fulfilling every customer order, ensuring the integrity of quoted and margin information, as well as the accuracy of order details.

- Once the product is receipted from production, SYSPRO will automatically update the order, and automatic alerts can be set up either internally to sales or accounting teams, or directly to customers.

Improve Supply Chain Efficiency

- Time-phased aggregate materials planning and purchasing is facilitated though SYSPRO’s material requirements planning, forecasting and replenishment policy features.

- For companies looking for a simpler replenishment approach not requiring full-scale MRP, SYSPRO offers Advanced Trial Kitting. This enables you to limit materials orders based on a range of user-selected criteria, avoiding waste.

- SYSPRO ERP software provides true order-linked pull replenishment through sales order- and purchase order-to-job linking and multi-level trial kitting. Automatically raise and relevant supply orders via simple review.

- SYSPRO ERP software offers robust lot traceability and serial tracking features providing you with comprehensive product and component traceability.

Improve Scheduling and Reduce Production Costs

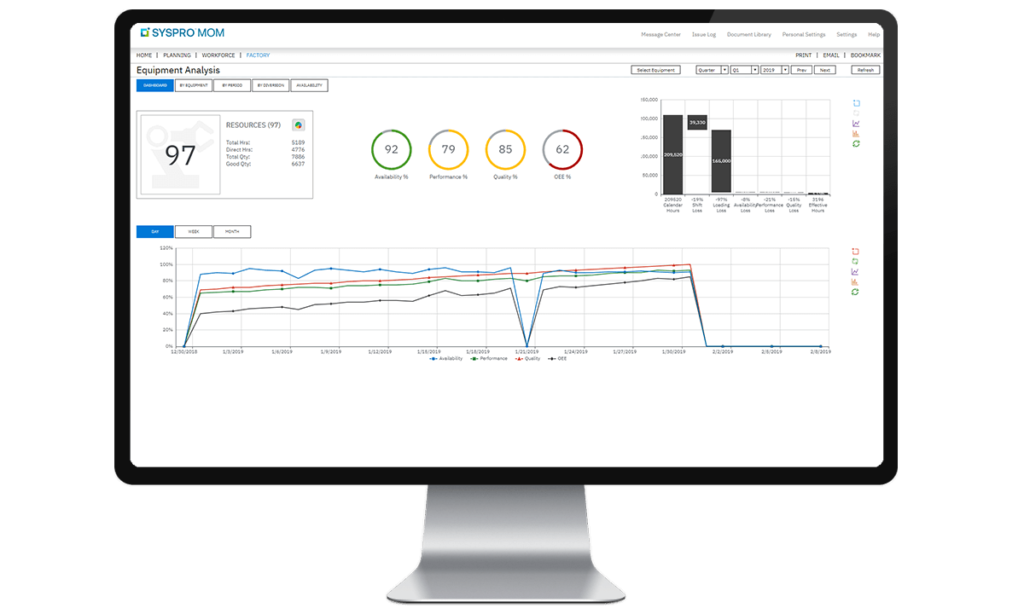

- SYSPRO Manufacturing Operations Management (MOM), powered by LYNQ, is a powerful tool for scheduling, sequencing and synchronizing of jobs and operations on the factory floor. Manage and control events seamlessly to reflect the dynamic and versatile nature of your production environment. And, with real-time information at your fingertips, more effectively quote realistic lead times and delivery dates.

- With SYSPRO’s Work in Progress module you can execute jobs efficiently and conduct day-to-day monitoring of job-related activities, costs, scrap and exception events. Material and labor consumed in production may be backflushed or, for longer jobs, issued to work-in-progress in real-time.

Best-in-Class Make to Order Manufacturing ERP

Success in make-to-order or build-to-order manufacturing means delivering high quality, value and speedy delivery – all while keeping a tight rein on materials and inventory costs.

Contact us to learn more about how SYSPRO can help you meet these goals, with an ERP platform purpose-built to meet the needs of manufacturers.